Mold-Free Robotic Roller Hemming System

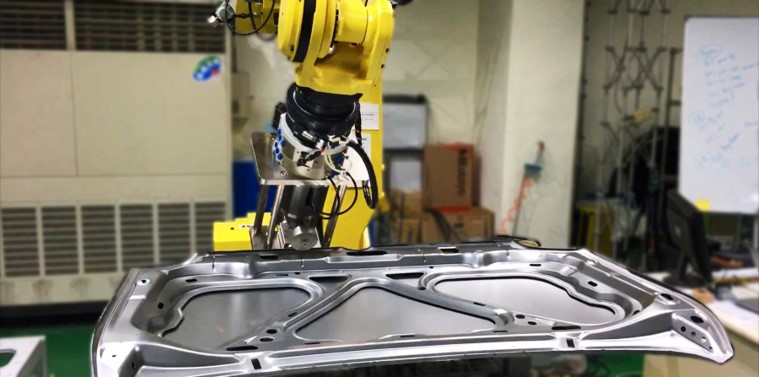

The high requirement of small volumes with large-variety, especially in the automotive aftermarket, enforce manufacturers to develop strategy for avoiding using molds now. Hemming is a key process to combine two car sheets together, but molds are required in traditional methods. This system aim to help such manufacturers to hem various kinds of sheets without molds. Besides, we also develop the software for optimized trajectory planning to avoid poses of singularity, joint limit, collision and low-stiffness.

A test was conducted for testing whether wheel-wheel design could hem flat sheets as well as wheel-mold design did, and the result indicated that the wheel-wheel design could meet the requirement.

The following tests will focus on how to hem irregular metal sheets. That is what we consider the major value of it because the more irregular forms require more complex and expensive molds. We plan to make a debut of this system in Taiwan Automation Intelligence and Robot Show in 2021.

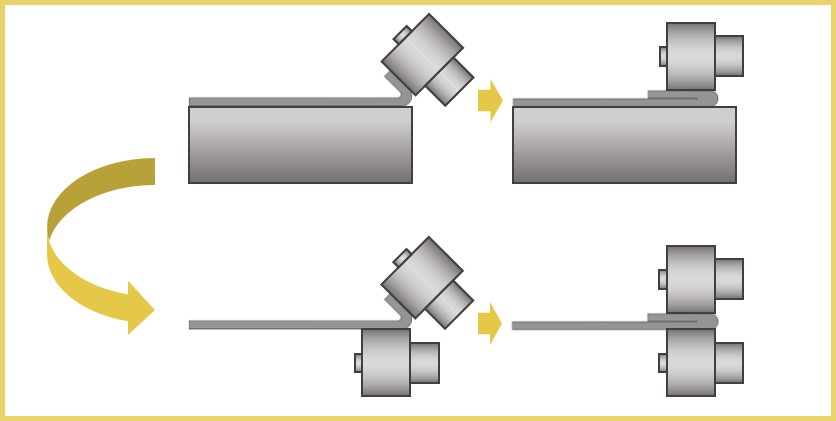

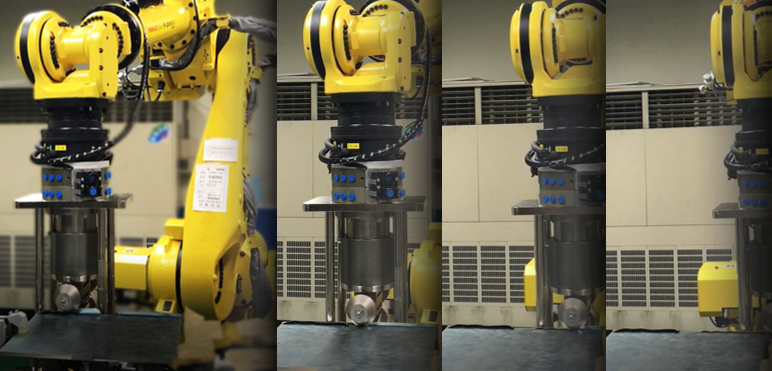

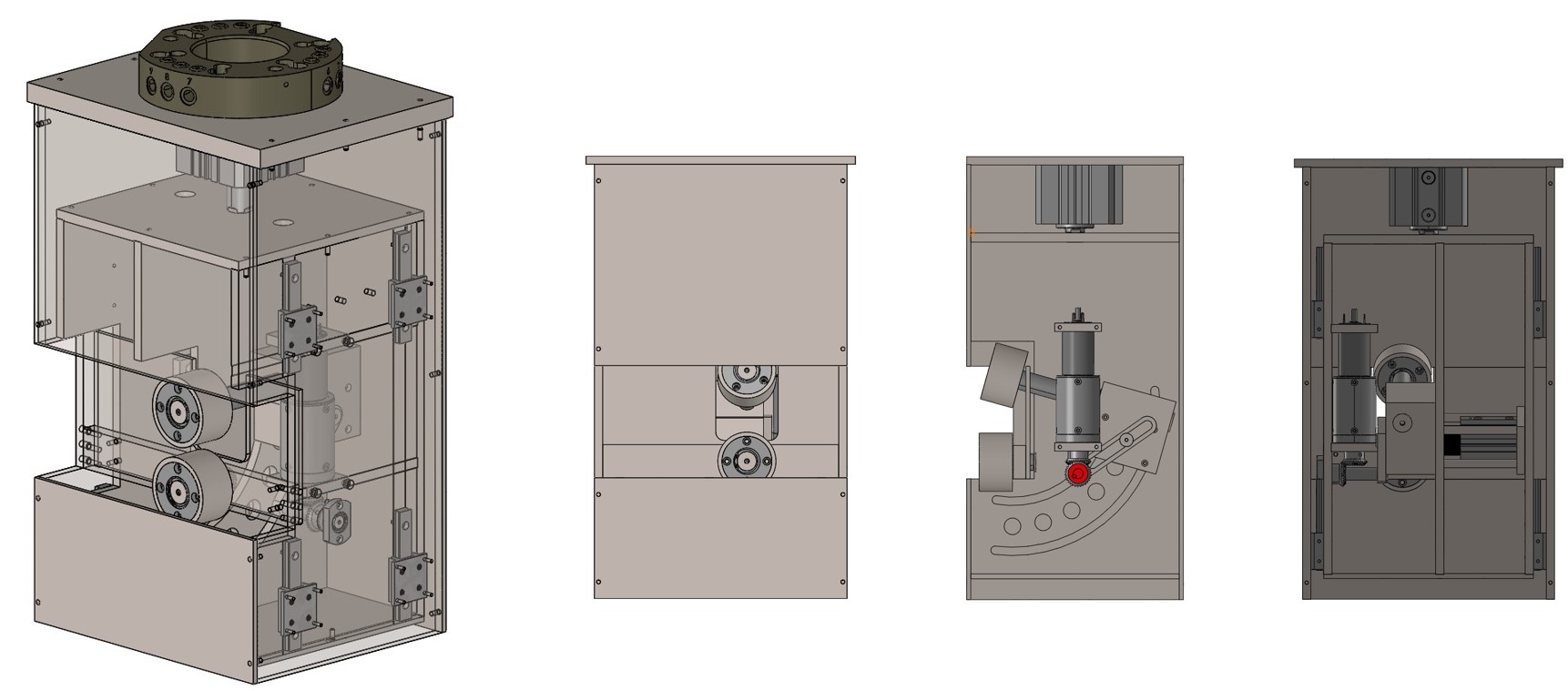

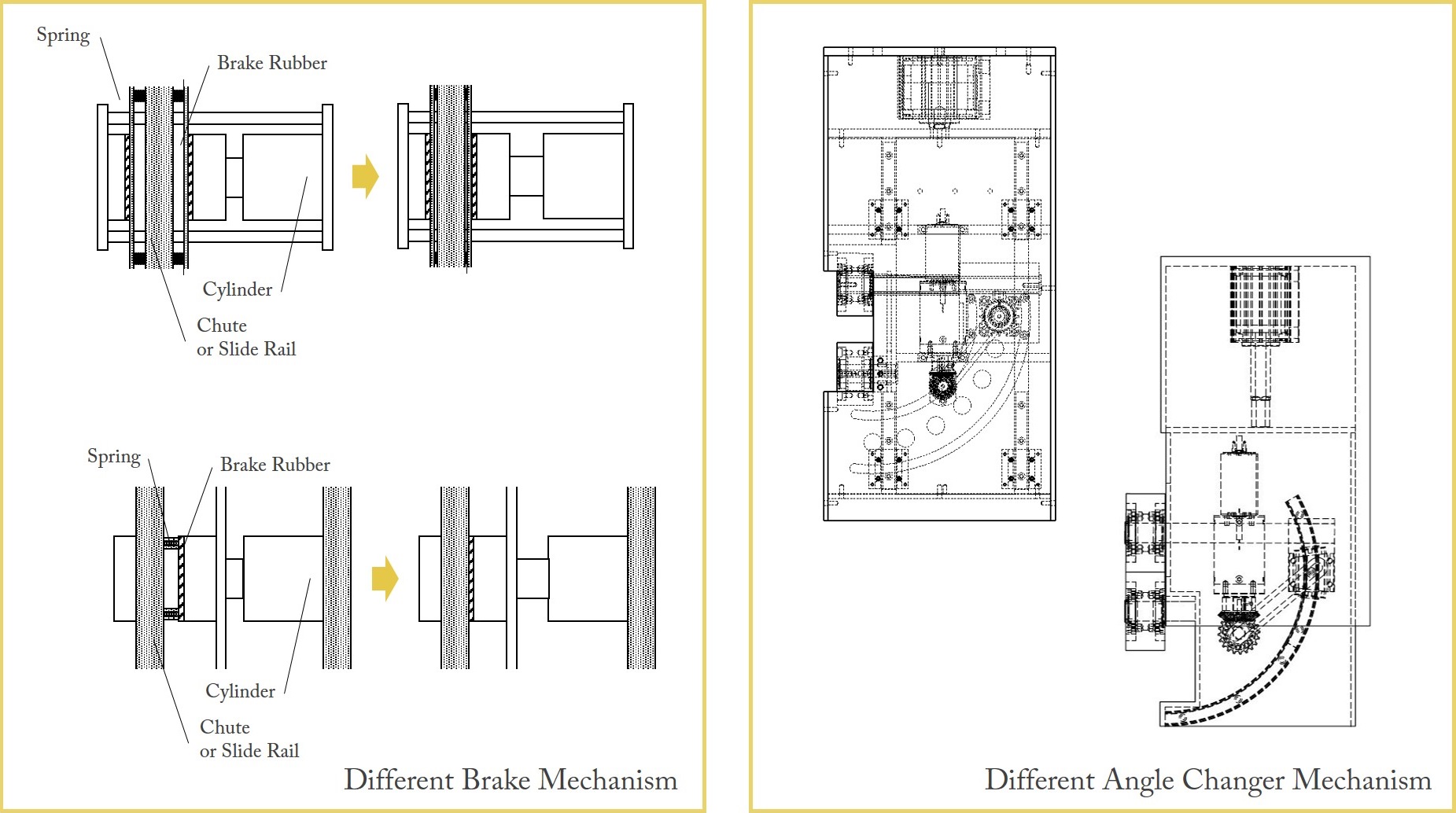

In the roller hemming process, it usually takes more than 2 times to hem the sheet degrees by degrees, or the wrinkle will appear. Thus the wheels with different angle need to be replaced in a single process when traditional roller hemming tools are used. To reduce the time of replacing wheels and make the tool more flexible, I design a new type that can adjust the angle between two wheels automatically. We are applying the patent now.

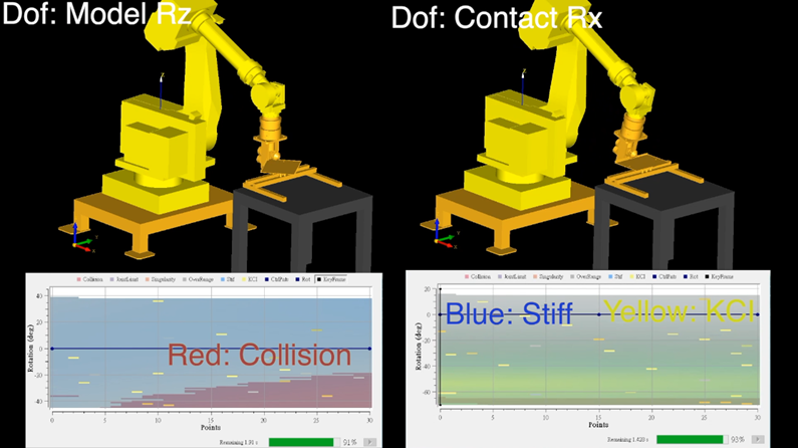

Our software has four color layers to represent singularity, joint limit, collision and stiffness respectively. Users can adjust parameters of joints in joint space to avoid above poses. We focus on developing the layer of stiffness to represent different scale by different color depth.

By applying the stiffness matrices, users can plan the trajectory with relatively high stiffness to perform a task. In this way, manufacturers can choose lower payload robots to perform the same task as higher payload robots do.