Composite Pressure Sensor

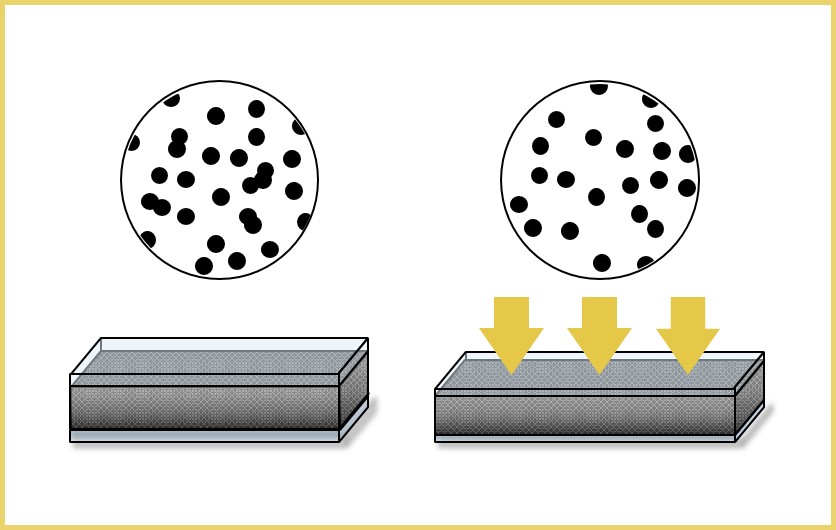

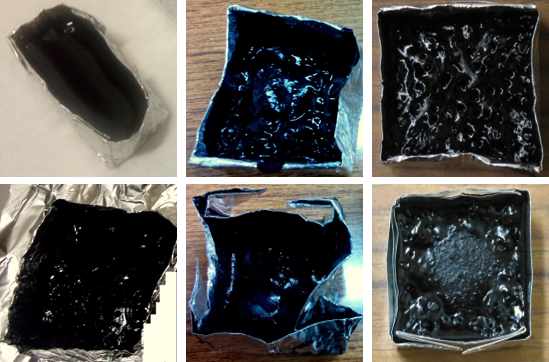

This conductive-elastic pressure sensor, which could detect foot pressure, was fabricated by mixing two materials, carbon-black and PDMS. Carbon-black was a kind of conductive powder, and PDMS was a kind of flexible substance. When pressure was applying, the space between particles would change and thus the conductivity of the sensor would be different. I used this poverty to design a foot pressure sensor, which had enough strength to bear human weight, as well as enough flexibility for comfort for foot.

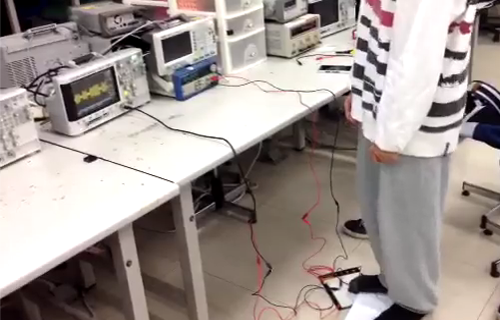

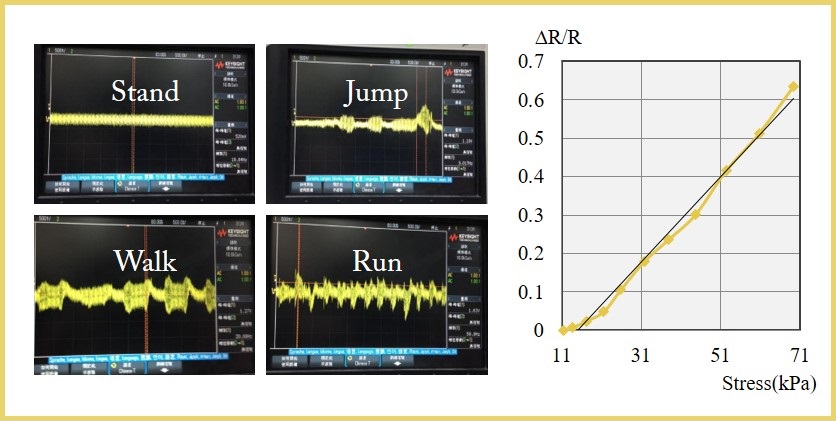

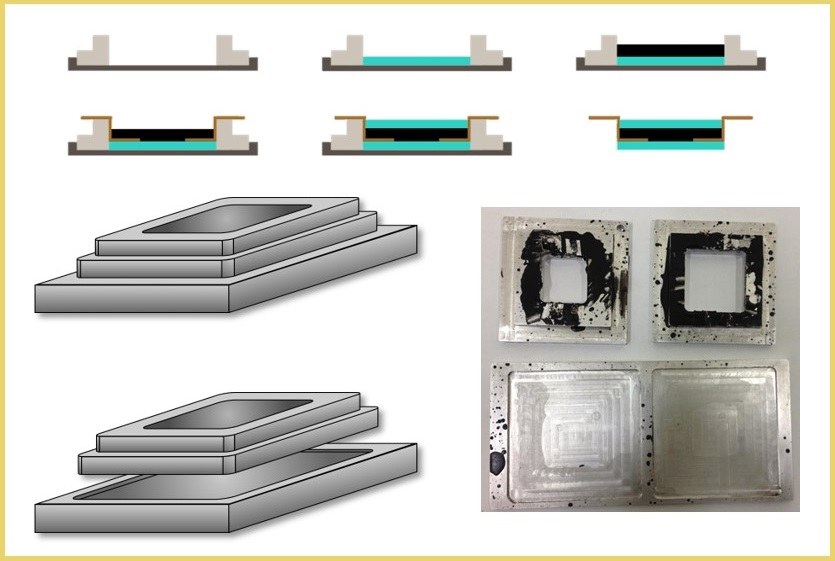

I optimized the proportion of two materials and designed the sandwich-like structure for the best result. The proportion affected the flexibility and conductivity, and the structure made it possible to bear human weight. Even though the noise became a major issue, the test of motion detection reveled that it had the ability to detect different motions. The relationship between resistance and stress demonstrated that it had the ability to detect different stress as well.

The mold was designed and made by myself. The advantage was that the final product could be taken out easily as the upper mold was separated. I also designed the rounded corner of the mold for reducing adhesion between the sensor and the mold.

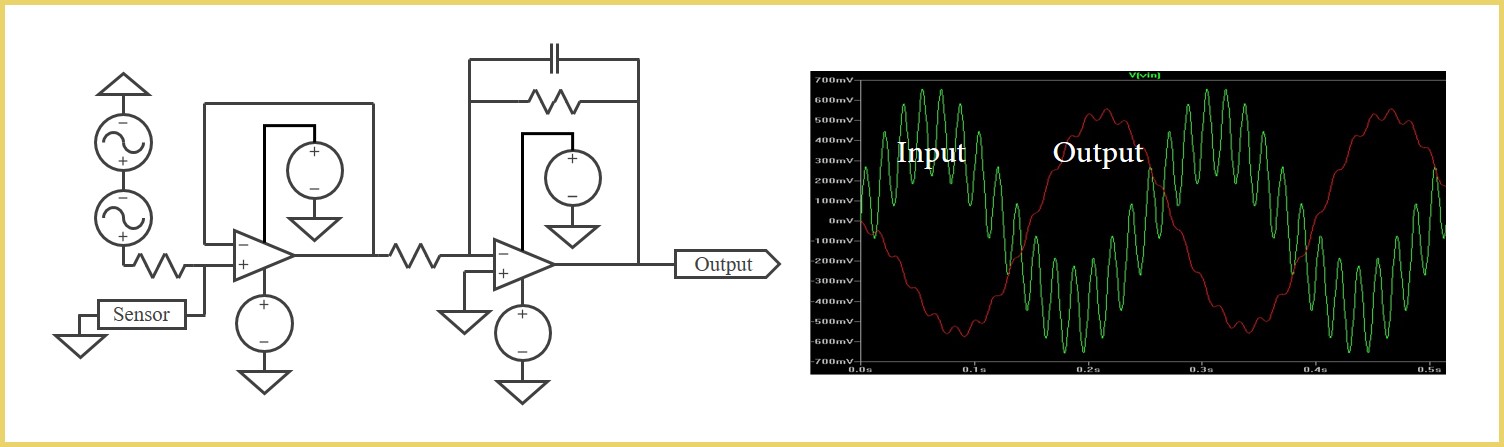

The simulation of low pass filter circuit indicated that the high frequency noise could be filtered. The research continued by a colleague in Medical Engineering Lab, NCTU.